产业链近日消息称,苹果已经确认把笔记本电脑的摄像头订单下放给越南舜宇,以配合越南富士康的生产,向全球出货。

消息显示,由于苹果iPhone新机增加一颗主摄像头像素升级到4800万像素,因此苹果摄像头供应链产能全部出现紧张态势。

事实上,从苹果采用4800万像素的摄像头开始,索尼的摄像头芯片就出现了产能吃紧现象,当时索尼芯片后段产能不足,还向台积电旗下的采钰扩大彩色滤光膜订单。目前索尼仍然在芯片生产的多个环节,寻找台积电的合作,来解决产能问题。

索尼目前最新的手机4800万像素CMOS传感器堆叠增加到了三层,而且传感器的面积更大由1/1.68英寸增加到了1/1.3英寸,所以索尼产线的产出率大幅下降。所以当苹果再把4800万像素CMOS传感器订单数量翻倍时,索尼就只能削减其它品类的订单了。

为了应对索尼的缺货,苹果有意让三星重回苹果手机的摄像头供应链,目前已经开始对三星的iPhone16系列机型的摄像头产品进行最终质量测试。因为去年索尼在iPhone15手机上市后,产能供应曾出现紧张的局面导致出货延迟,因此苹果不得不重新考重新引入其它CIS芯片的供应商。

虽然从去年开始中国大陆多家12吋晶圆厂产能开出,全球的高端CIS产能仍然比较紧。除了苹果寻找三星代工4800万像素CIS芯片以及前摄CIS芯片外,行业其它客户也建议海力士重启CIS芯片生产。

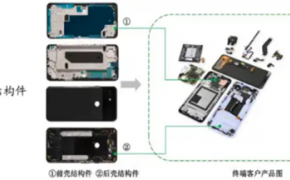

另外近年来苹果在中国大陆的摄像头供应链产能,几乎全部出售给了中资企业,这些企业在出售了中国大陆的产能后,有些完全退出了这个行业,有些则在海外其它地区扩建的产能还没完成,所以目前苹果销往中国大陆以外市场的产品,主要靠越南的LGInnoTek来供应,当苹果加在订单产能的时候,越南LGInno Tek的产能也出现吃紧。

苹果为了保证出货速度与数量,开始把除iPhone主摄摄像头产品之外的订单,交给三星和越南舜宇。目前越南舜宇最先获得的是苹果笔记本电脑的摄像头模组订单,同时舜宇也自己提供相关的镜头配套。

舜宇最早从2019年6月在越南河内光明工业园区成立舜宇浙江光学越南新工厂,标志着舜宇越南布局的开始。随后舜宇在越南投资了舜宇光电、舜宇汽车、舜宇红外、舜宇Opotec等4个项目,专业生产车用红外镜头、手机摄像头模组、监控摄像头,主要在永福省、永福省和河内周边,仅在太原,舜宇光电就投资了1.1亿美元的摄像头模组光学制造、加工和组装项目。

去年舜宇继续在越南扩张,3月太原政府和舜宇签订投资备忘录,舜宇将继续在当地投资20亿美元。去年九月,舜宇光学在越南继续扩产之路,在越南义安省WHA工业园区建厂,占地42.8公顷,总投资1.5亿美元,用于生产电子元件,该厂预计将于2025年第四季度投产,计划雇佣近2万名工人。

随着苹果对越南舜宇的验厂通过,以及越南舜宇新产能的不断开出,行业认为越南舜宇将成为越南LGInno Tek外的第二苹果摄像头模组供应商,未来营收业绩将有明显的增长。

据产业链传出的消息称,由于全球贸易环境变化,苹果未来在中国大陆的供应链将只生产在中国大陆销售的产品,其它销往全球其它地方的产品,则将视各个市场的关税贸易政策,安排在其它第三方市场生产,至于会不会重启美国本土生产,则要看苹果和富士康的共同设计的自动化工厂运行成本而定。

The industrial chain recently reported that Apple has confirmed to place an order for laptop cameras to Viet Nam Sunny to cooperate with the production of Viet Nam Foxconn and ship to the world.

According to the news, due to the addition of a main camera pixel to Apple's new iPhone to upgrade to 48 million pixels, the production capacity of Apple's camera supply chain is all tense.

In fact, since Apple's adoption of 48 million pixel cameras, Sony's camera chips have been tightened in production capacity. At present, Sony is still looking for TSMC cooperation in multiple links of chip production to solve the production capacity problem.

Sony's latest mobile phone 48 million pixel CMOS sensor stack has increased to three layers, and the sensor area is larger from 1/1.68 inch to 1/1.3 inch, so the output rate of Sony's production line has dropped significantly. So when Apple doubles the number of orders for 48 million pixel CMOS sensors, Sony will have to cut orders for other categories.

In response to Sony's shortage, Apple intends to bring Samsung back into the camera supply chain for Apple's mobile phones, and has now begun to conduct final quality tests on Samsung's iPhone 16 series camera products. Because Sony had a tight supply of production capacity after the launch of the iPhone 15 mobile phone last year, resulting in a delay in shipments, Apple had to re-examine and reintroduce other CIS chip suppliers.

Although the production capacity of many 12-inch wafer fabs in Chinese mainland has been released since last year, the global high-end CIS production capacity is still relatively tight. In addition to Apple's search for Samsung foundry 48 million pixel CIS chips and forward-looking CIS chips, other customers in the industry have also suggested that Hynix restart CIS chip production.

In addition, in recent years, Apple's camera supply chain capacity in Chinese mainland has almost all been sold to Chinese-funded enterprises, and after these companies sold their production capacity in Chinese mainland, some have completely withdrawn from this industry, and some have not completed the expansion of production capacity in other overseas regions, so at present, Apple's products sold to markets outside Chinese mainland are mainly supplied by LGInnoTek in Viet Nam, and when Apple adds order capacity, LGInno in Viet Nam Tek's production capacity is also tight.

In order to ensure the speed and quantity of shipments, Apple began to hand over orders other than iPhone main camera products to Samsung and Viet Nam Shunyu. At present, Viet Nam Sunny is the first to obtain an order for the camera module of Apple's laptop, and Sunny also provides relevant lens packages by itself.

As early as June 2019, Sunny established a new factory of Sunny Zhejiang Optical Viet Nam in Guangming Industrial Park, Hanoi, Viet Nam, marking the beginning of Sunny's Viet Nam layout. Subsequently, Sunny invested in 4 projects in Viet Nam, including Sunny Optoelectronics, Sunny Automobile, Sunny Infrared, and Sunny Opotec, specializing in the production of automotive infrared lenses, mobile phone camera modules, surveillance cameras, mainly in Vinh Phuc Province, Vinh Phuc Province and around Hanoi, in Taiyuan alone, Sunny Optoelectronics has invested 110 million US dollars in camera module optical manufacturing, processing and assembly projects.

Last year, Sunny continued to expand in Viet Nam, and in March the Thai Thai government signed an investment memorandum with Sunny that Sunny will continue to invest US$2 billion in the country. Last September, Sunny Optics continued its expansion in Viet Nam, building a 42.8-hectare factory in WHA Industrial Park, Nghe An Province, Viet Nam, with a total investment of US$150 million for the production of electronic components, which is expected to start production in the fourth quarter of 2025 and plans to employ nearly 20,000 workers.

With Apple's inspection of Viet Nam Sunny and the continuous opening of new production capacity of Viet Nam Sunny, the industry believes that Viet Nam Sunny will become the second Apple camera module supplier outside Viet Nam LGInno Tek, and the future revenue performance will increase significantly.

According to the news from the industrial chain, due to changes in the global trade environment, Apple's future supply chain in Chinese mainland will only produce products sold in Chinese mainland, and other products sold to other parts of the world will be arranged to be produced in other third-party markets depending on the tariff and trade policies United States of each market.